HubPilot News Mitsubishi Electric Debuts HubPilot Autonomous Distribution Yard Logistics Platform

Mitsubishi Electric Automotive America, which has facilities in Northville Township, has introduced the HubPilot autonomous distribution yard logistics platform as a service (PaaS).

The technology, the first in the market to leverage a unique combination of software, on-vehicle sensing, and infrastructure-based perception with high-definition mapping for precise localization, is poised to transform logistics and distribution centers.

“The HubPilot platform utilizes infrastructure-based perception in conjunction with rover perception to make the intelligent decisions necessary for industry-leading yard management,” says Mark Rakoski, vice president of advanced engineering at Mitsubishi Electric Automotive America. “This technology provides increased safety and security and optimizes logistics efficiency.”

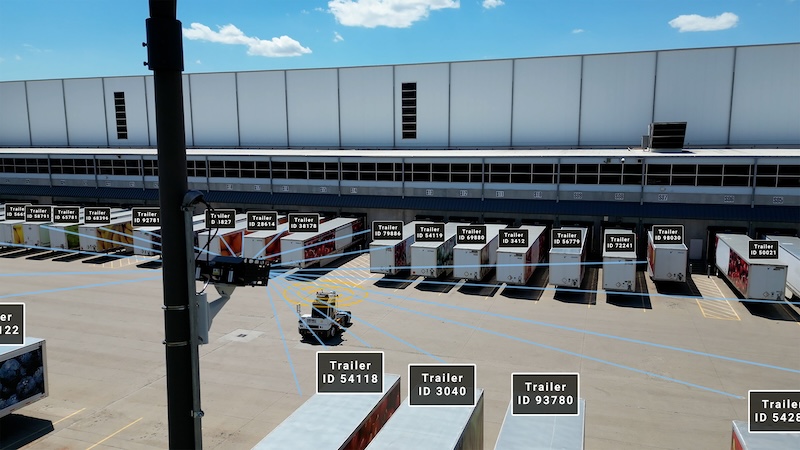

Designed specifically for geofenced distribution centers and logistics hubs, the HubPilot platform employs optimized multi-sensor inputs on autonomous yard dogs, also known as rovers or terminal tractors. These sensors, combined with advanced software, allow the platform to visualize the yard dogs’ surroundings, identify assigned trailers, and confirm their locations using the HubPilot platform.

“Utilizing real-time data and visualization, the yard dogs autonomously connect with trailers and transports them to designated locations, all while maintaining constant awareness of their surroundings to avoid contact with stationary and moving objects, including people,” says Eyad Zeino, director of mobility at Mitsubishi Electric Automotive America.

In addition, the HubPilot platform automates the connection of compressed air hoses to the trailer to operate the air brakes, eliminating the need for manual intervention each time a yard dog picks up or drops off a trailer. Trailers are virtually “tagged” so the HubPilot platform can track their location and movements in real time.

The platform interfaces with the yard management system (YMS) to receive commands, operating at SAE Level 4 autonomy. Yard dogs also can be operated manually by a driver with the platform maintaining the same security, safety, and optimization benefits.

Rakoski notes that airports, shipping ports, and large manufacturing facilities — anywhere that trailers and goods are moved — represent additional potential applications for the HubPilot platform, which serves as another steppingstone toward broader autonomy on streets and highways.

“The HubPilot platform will help alleviate the increasing driver shortage and improve safety, security, and working conditions,” Zeino says. “The technology can be used anywhere there are moving vehicles, and the infrastructure-mounted LIDAR eliminates blind spots that can’t be avoided with on-vehicle technology. A busy yard has a lot of different vehicles and trailers moving simultaneously, and the HubPilot platform provides a safe way for the rovers and trailers to navigate.”

The HubPilot platform integrates sensors on both the vehicles and the infrastructure — such as buildings or poles — within the yard, enabling two-way communication that enhances safety and efficiency. Unlike competing models that have sensors only on the vehicles, the HubPilot platform provides full coverage of the area, eliminating blind spots and even detecting pedestrians in the yard.

Mitsubishi Electric Automotive America engineered the HubPilot platform with advanced safety and cybersecurity measures to prevent the platform from interference from outside sources or from being accessed by hackers. It also improves security within the yard by providing 24/7 monitoring, which reduces theft and vandalism.

The company continues in the development phase of the HubPilot Platform in 2024 and will be fully operational in 2025. MEAA plans to initially launch the HubPilot platform in the North American market, but the platform has the potential for global deployment.

Mitsubishi Electric Automotive America was established in 1979 to serve the North American automotive, heavy-duty truck, and coach business. The comapny offers a wide range of products and services, including passenger entertainment systems, car navigation systems, screens, head units, amplifiers, and powertrain products such as starters and alternators.

For more information, visit www.meaa-mea.com.